Introduction of Single Man Lift

Single man lift, also known as self-propelled vertical mast lifts or aerial work platforms, are mobile elevating work platforms (MEWPs) designed to provide safe and efficient access to overhead areas. They are characterized by a vertical mast structure that supports a work platform, allowing workers to perform tasks at height with stability and maneuverability. The “self-propelled” aspect means these lifts have integrated drive systems, allowing operators to move the lift horizontally while elevated, enhancing productivity and reducing the need for manual repositioning.

Features

Cylinder holding valve: This single man lift critical safety feature prevents the platform from descending rapidly in case of a hydraulic hose failure. It essentially locks the hydraulic fluid in the cylinder, maintaining platform position.

Emergency stop button: Easily accessible buttons (often multiple) that immediately cut power to all lift functions, halting movement in emergency situations.

Two controllers operation: Allows operation from both the platform and the base of the lift, providing flexibility and control for different work scenarios.

Emergency lowering system: A backup system (often manual or battery-powered) to lower the platform safely in case of primary power failure.

Leveling sensor: Ensures the platform remains level even on uneven ground, enhancing stability and preventing tipping hazards.

Forklift pockets: Allow for easy and safe transportation of the lift using a forklift, simplifying logistics and movement on-site.

All motion alarm: An audible alarm that sounds during any lift movement (up, down, or horizontal travel), alerting those nearby to the lift’s operation.

Transport tie hole: Secure points on the lift’s chassis for tying it down during transport on a truck or trailer, preventing movement and damage.

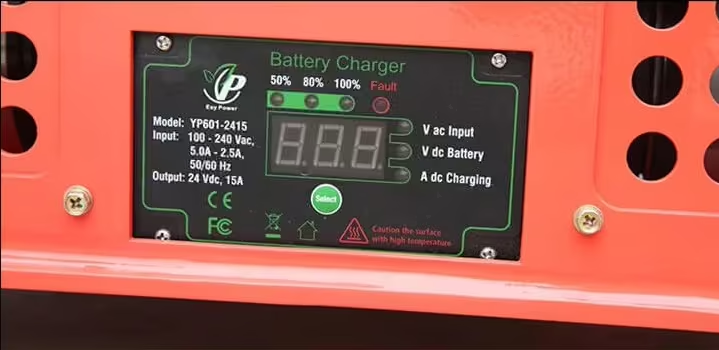

Battery charger indicator: Displays the battery’s charge level, preventing unexpected downtime and ensuring the lift is ready for use.

Electric limit switch: Automatically stops lift movement at pre-set height limits, preventing over-extension and potential damage to the machine.

Automatic pothole protection: Automatically deploys when the lift encounters a pothole or uneven surface, increasing stability and preventing tipping.

Drivable at full height: Allows the operator to move the lift horizontally even when the platform is fully elevated, increasing efficiency and reducing the need to lower and reposition frequently.

Onboard diagnostic system: Provides information about the lift’s systems, aiding in troubleshooting and maintenance, reducing downtime.

Application of Single Man Lift

Single man lift are versatile and find applications in various industries and settings:

- Warehousing and Logistics: Used for order picking, inventory management, and maintenance tasks in warehouses and distribution centers.

- Retail: Ideal for stocking shelves, changing light bulbs, and performing maintenance in retail stores and shopping malls.

- Construction and Maintenance: Utilized for various tasks such as painting, electrical work, HVAC installation and repair, and general maintenance in construction sites and facilities.

- Manufacturing: Employed for maintenance, repairs, and installations in manufacturing plants and factories.

- Facility Management: Used for cleaning, painting, and general maintenance in office buildings, schools, hospitals, and other facilities.

Advantage

- Vertical Mast Design: The vertical mast provides stable vertical movement, allowing precise positioning at height. Some models feature telescopic masts for increased reach.

- Self-Propelled Functionality: Integrated drive motors and controls enable operators to move the lift forward, backward, and steer while on the platform, improving efficiency and maneuverability.

- Compact Footprint: Often designed with a narrow base, these lifts can operate in confined spaces, such as narrow aisles, hallways, and crowded work areas.

- Precise Positioning: The combination of vertical movement and self-propelled functionality allows for precise positioning and access to specific work areas.

- Safety Features: Equipped with safety features such as guardrails, outriggers (on some models), emergency lowering systems, and tilt sensors to ensure operator safety.

- Electric Power: Most self-propelled mast lifts are electrically powered, making them suitable for indoor use and producing zero emissions. Some models may offer hybrid or dual-fuel options.

- Non-Marking Tires: Typically fitted with non-marking tires to protect sensitive flooring in indoor environments.

Parameter

1 | Model | AMWP3.6-6100 | AMWP4.8-6100 | AMWP6-6100 |

2 | Max. Working Height | 5.6m | 6.8m | 8m |

3 | Max. Platform Height | 3.6m | 4.8m | 6m |

4 | Loading Capacity | 227kg | 227kg | 159kg |

5 | Ext. Platform Capacity | 114kg | 114kg | 114kg |

6 | Overall Length | 1.36m | 1.36m | 1.36m |

7 | Overall Width | 0.76m | 0.76m | 0.81m |

8 | Overall Height | 1.7m | 1.98m | 1.98m |

9 | Platform Dimension | 1.3m×0.7m | 1.3m×0.7m | 1.3m×0.7m |

10 | Ext. Platform Length | 0.51m | 0.51m | 0.51m |

11 | Wheel Base | 1.04m | 1.04m | 1.04m |

12 | Inner Turning Radius | 0.3m | 0.3m | 0.3m |

13 | Outer Turning Radius | 1.8m | 1.8m | 1.8m |

14 | Travel Speed(Stowed) | 4km/h | 4km/h | 4km/h |

15 | Travel Speed(Raised) | 1.1km/h | 1.1km/h | 1.1km/h |

16 | Up/Down Speed | 31/32sec | 41.5/42sec | 52/53sec |

17 | Gradeability | 25% | 25% | 25% |

18 | Drive Tyres | Φ305×100mm | Φ305×100mm | Φ305×100mm |

19 | Drive Motors | 2×24VDC/0.5kW | 2×24VDC/0.5kW | 2×24VDC/0.5kW |

20 | Lifting Motor | 24VDC/1.2kW | 24VDC/1.2kW | 24VDC/1.2kW |

21 | Battery | 2×12V/100Ah | 2×12V/100Ah | 2×12V/100Ah |

22 | Charger | 24V/15A | 24V/15A | 24V/15A |

23 | Weight | 810kg | 980kg | 1060kg |

Part Detail of Single Man Lift

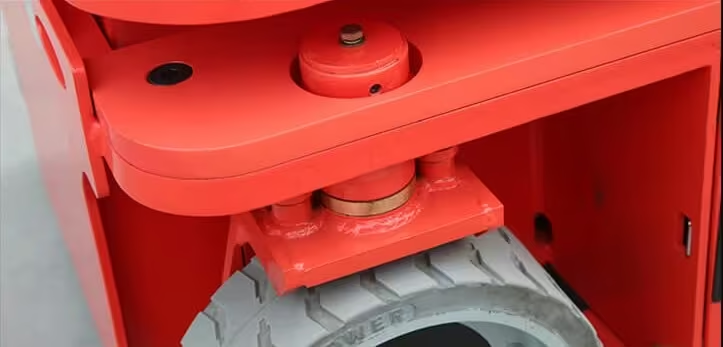

Automatic brak system

Tool box on the platform

Tilt sensor

Pump station

Non marking tyre

Ground control panel and buttton and charger

Fokrlift hole

Extendable platform

Contro panel on the platform